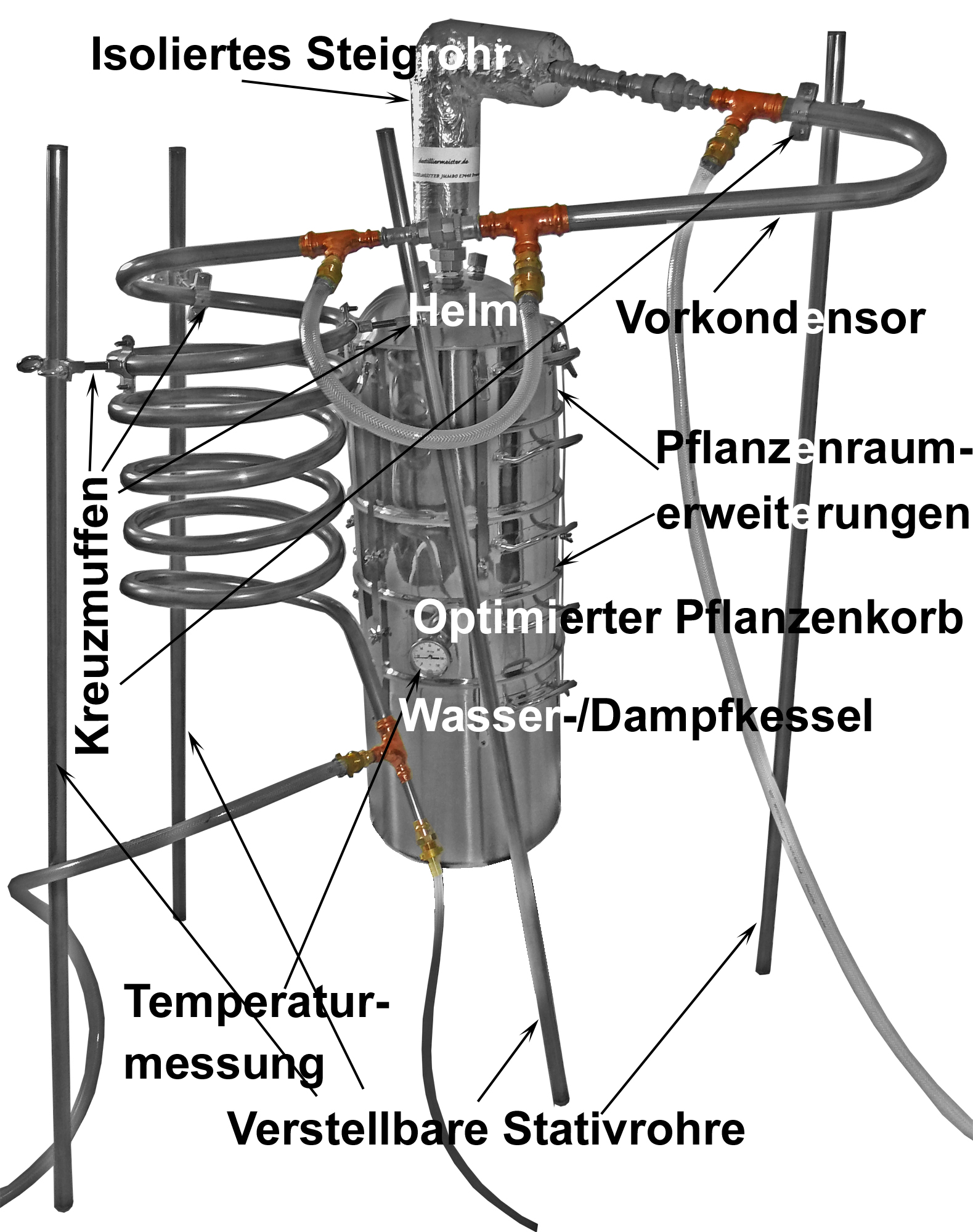

DISTILLIERMEISTER JUMBO-E7448-Premium-Plus - Model 2022 for external steam supply

Optimized distilling plant for steam distillation for the production of essential oil

Essential oils by steam distillation. The DESTILLIERMEISTER E7448-Premium-Plus model 2022 still is optimized for the extraction of essential oils. It has a drug volume of 48 liters, which in this version can be expanded by another 12 liters. Essential oil obtained by means of steam towing distillation has a particularly high quality because the temperature in the drug container remains below the evaporation temperatures of the water and the oils with this process, thus protecting the essential aromas. In particular, the stainless steel stills of the premium models of the DESTILLIERMEISTER E series work with a pressure-reducing pre-condenser, so that a particularly high product quality is achieved with these stills. After condensing the oil-bearing hydrosols in the pre-condenser, the downstream high-performance cooler cools the essential oils down to the required temperature.

For an optimal energy supply, a steam output of between 9 and 12 kW is required. In order to achieve this output, a heating output of between 23 and 30 kW would be required with an efficiency of 40%. This heat output is difficult to bring in via the bottom of the boiler. For this reason, the boiler on this shelf has also been equipped for the introduction of steam from an external steam generator. This steam generator should deliver 15 to 20 kg of saturated steam per hour. It can be either a steam generator or a kettle with a larger bottom diameter, from which the steam is introduced into kettle 1 using a flexible hose. To ensure that the efficiency of the steam introduced is not reduced too much, the steam is introduced via a diffuser connected to the ball valve.

-

Water / steam boiler: 25 liters,steam-dynamically optimized plant basket: 12 liters,

- Plant box enlargement: up to 3 x 12 liters

- Spherical helmet to reduce dripping loss.

- Insulated standpipe to prevent premature condensation.

- Precondensor to reduce pressure and temperature to preserve the essential aromas.

- High performance counter flow cooler

- Cooling system set up with a variable tripod so that the boiler can be reloaded independently of this.

- Ball valve and diffuser for external gas inlet.

DESTILLIERMEISTER JUMBO-E-7448 Premium Plus - Model 2022

-

Solid thick-walled water / steam boiler made of 18/10 stainless steel and three-layer thermo bottom,

-

Lockable with fasteners,

-

Hygiene by stainless steel.

Construction

-

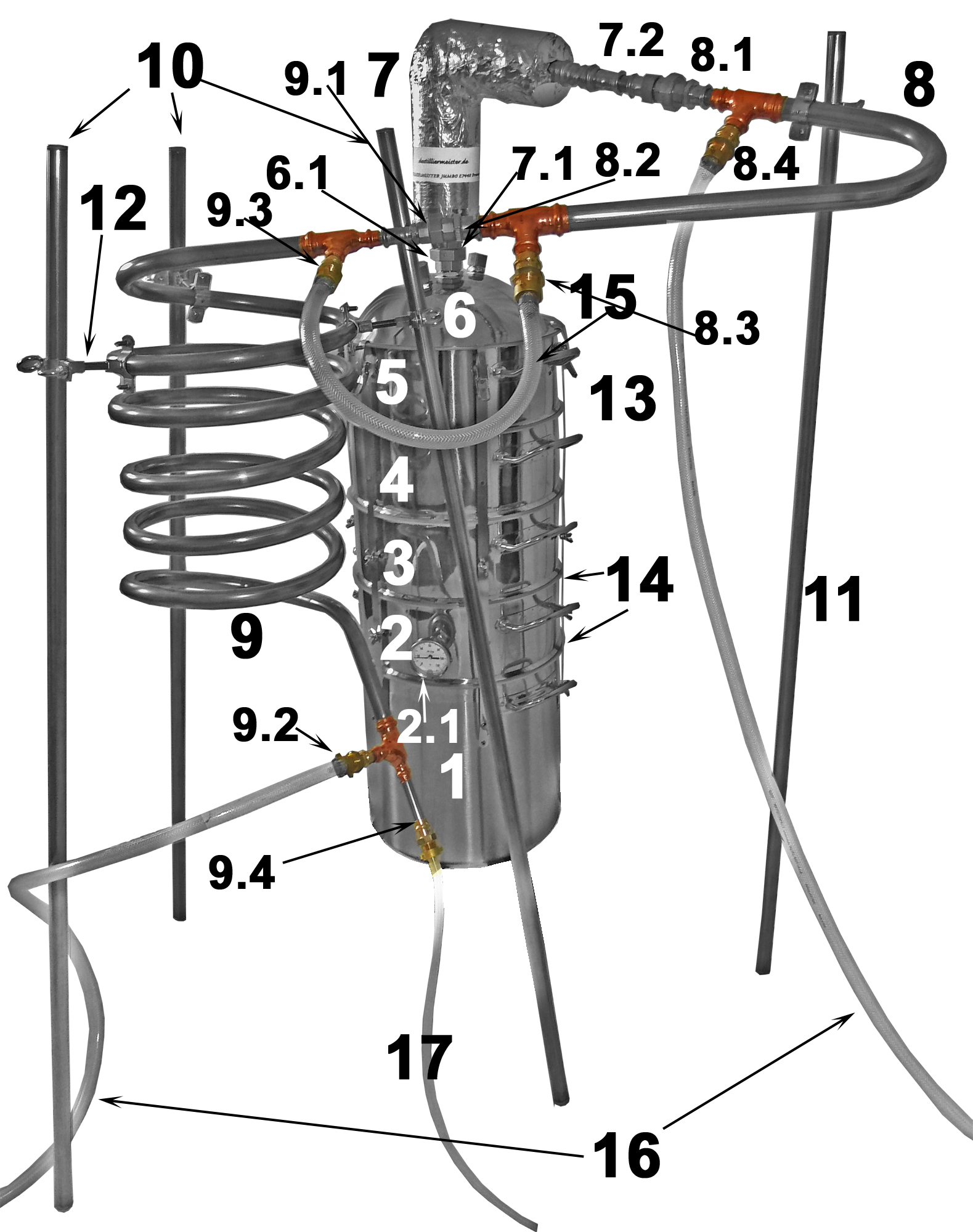

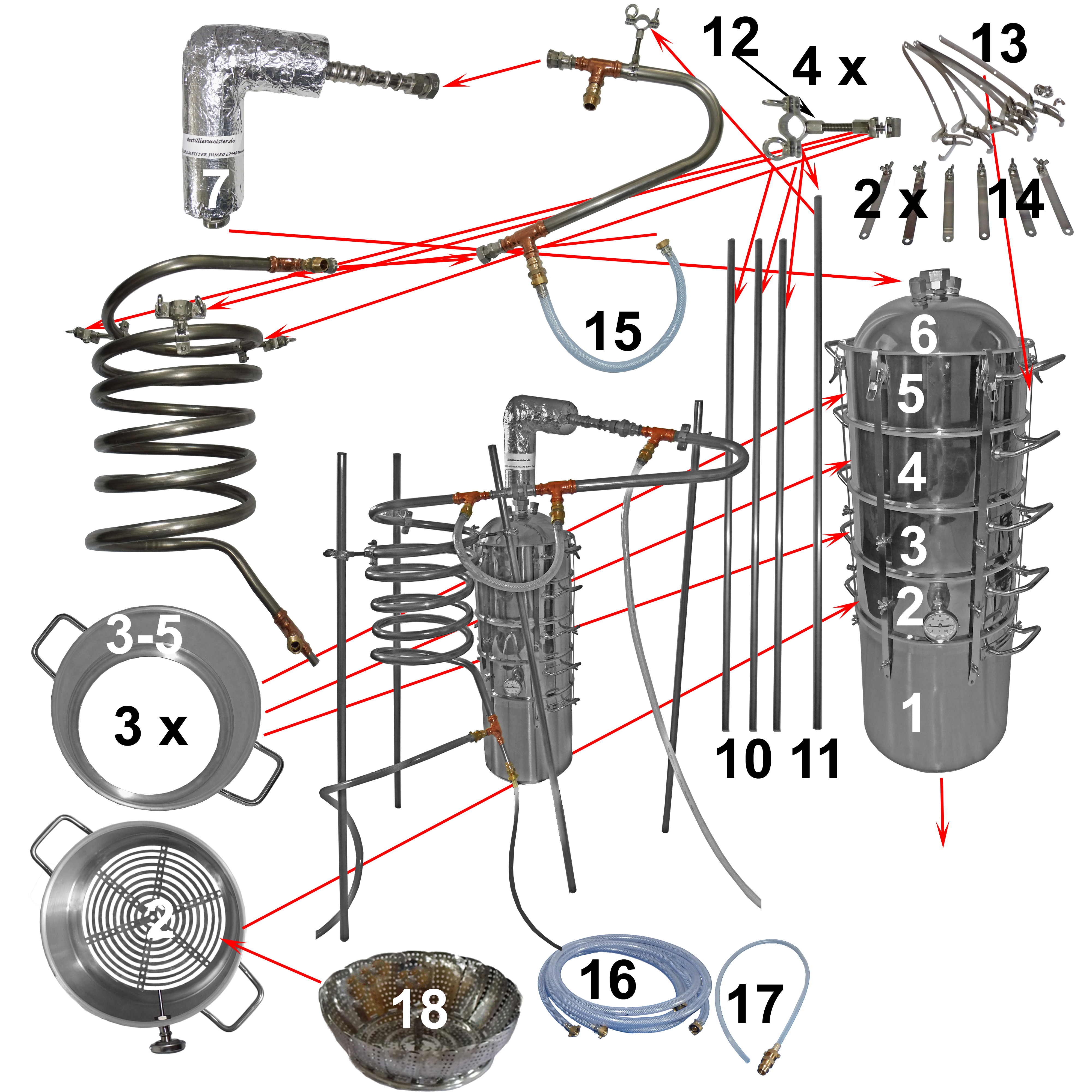

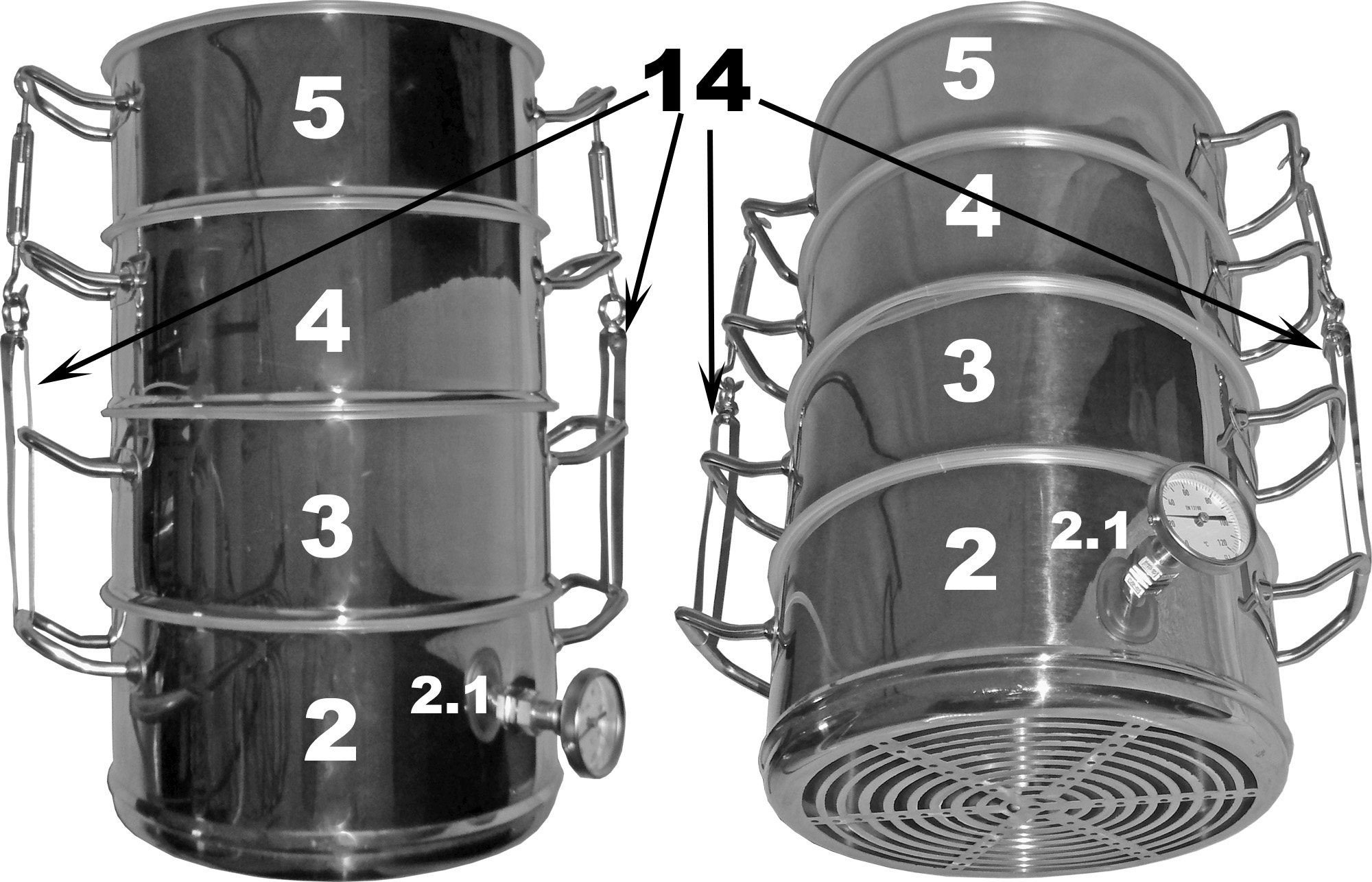

Boiler with ball valve and diffuser for steam introduction, volume 25 liters. If the boiler is initially to be heated directly, the above Extra volume in the boiler cannot be used. The maximum water capacity is then around 15 liters. The boiler must then be heated with at least 15 kW.

-

Lower plant basket with large opening ratio, 12 liters. The collapsible sieve 18 can be inserted for heavily crushed drugs. However, this should be avoided if possible, so as not to disturb the steam dynamics. In general, finer cuts can also be filled into the basket because the herbs interlock with each other. The plant parts that fall through at the beginning can be caught and refilled at the top.

-

Fixed stainless steel analog thermometer 0 -120 ° C, accuracy class 1 - easy to read.

-

or with a fine sieve

or with a fine sieve

-

-

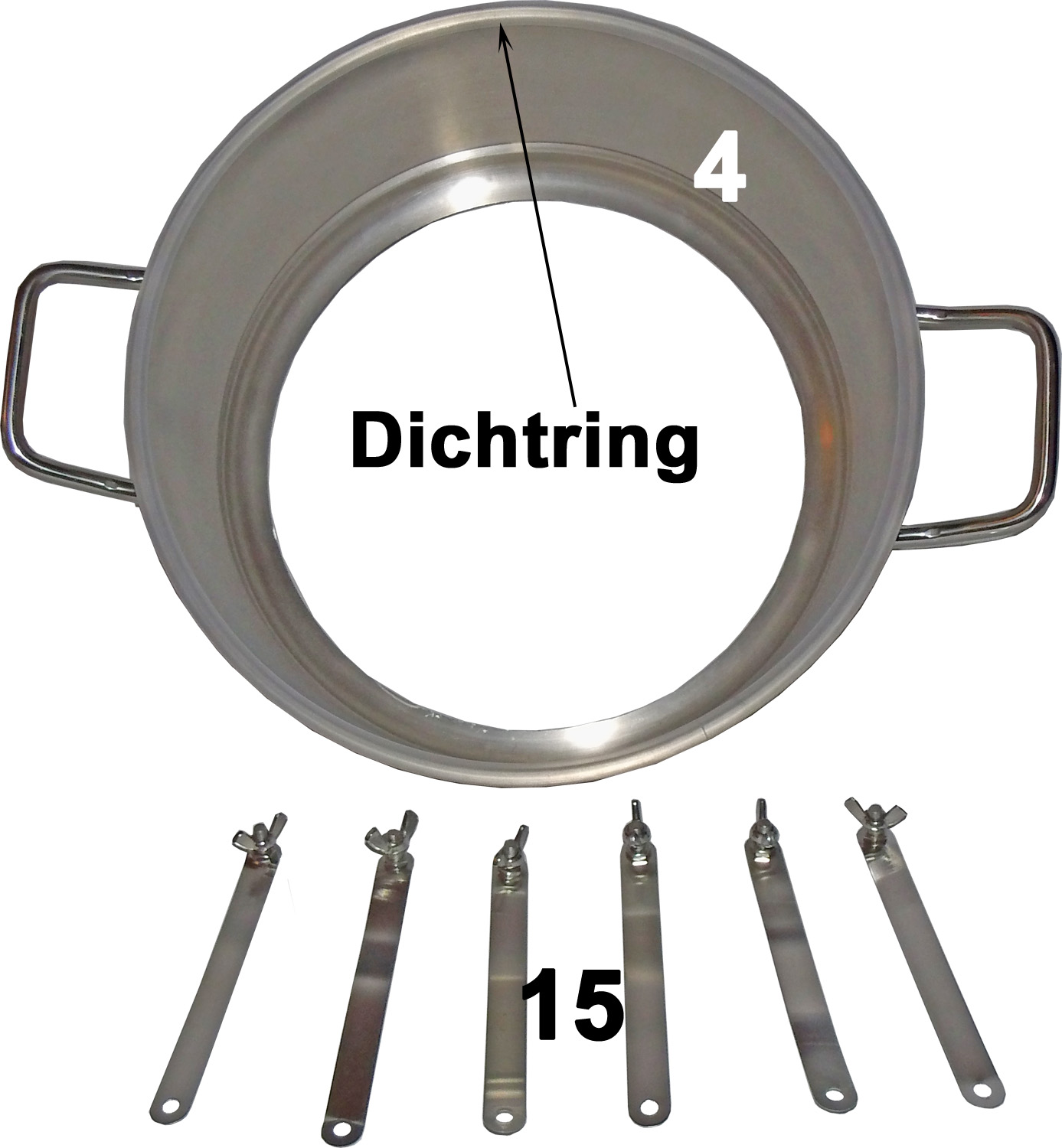

Plant box extension without bottom, 12 liters. The plant can also be operated for smaller margins without this extension. The fasteners are adjustable for this purpose.Up to 3 extension units of fresh plant material and 3 extension units of dried plant material can be used.

-

-

-

Second plant basket extension without bottom, 12 liters.

-

Third plant basket extension without bottom, 12 liters.

-

Spherical helmet.

-

Screw connection (6.1) for the riser (7).

-

Another stainless steel analog thermometer 0 -120 ° C to get temperature on the top.

-

-

-

Isolated riser.

-

Screw nipple for screwing with 6.1, 1".

-

Screw connection for the precondensor 8, 3/4".

-

-

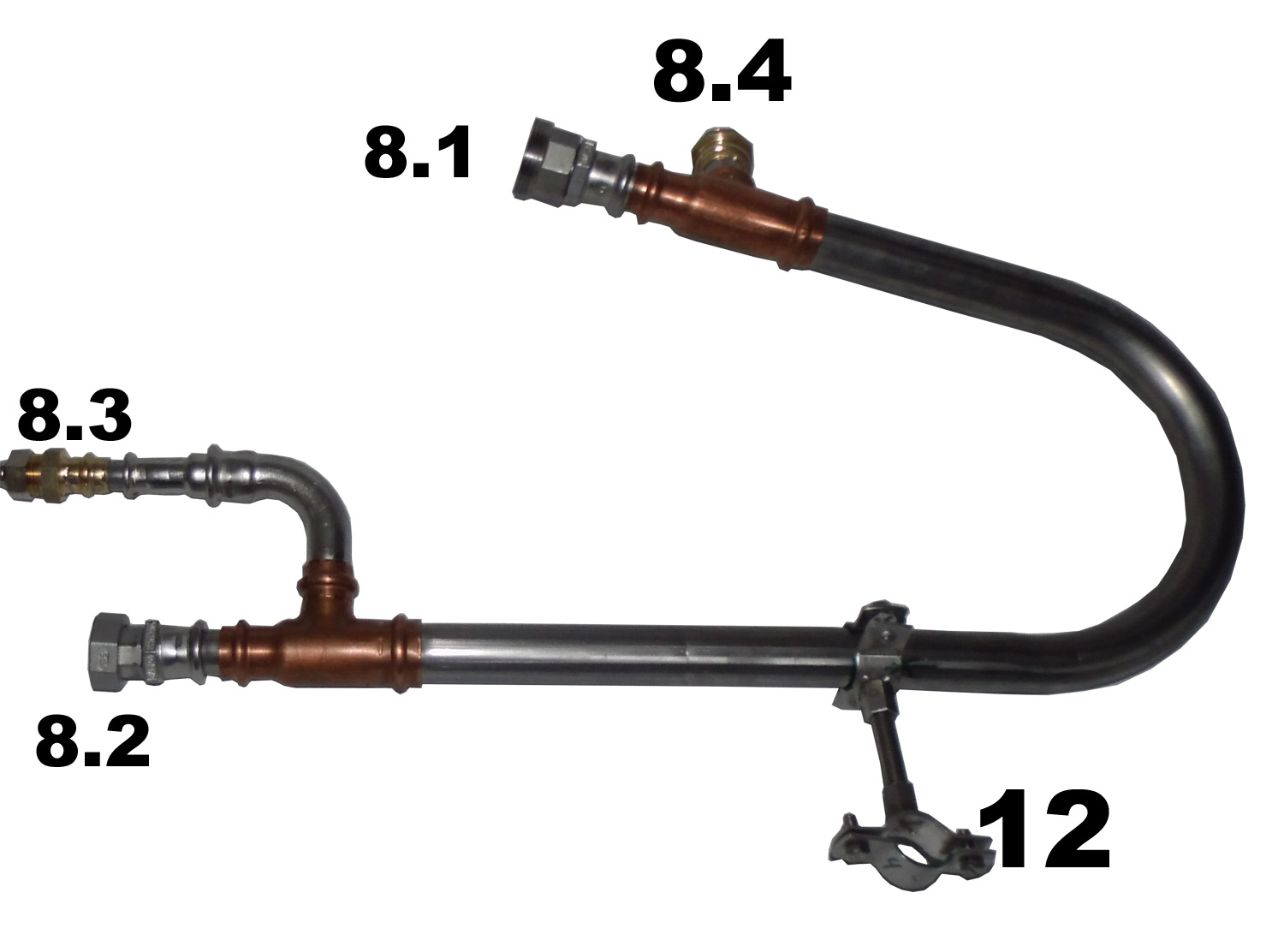

Pre-condenser for condensing the steam-oil mixture. Cooling length at least 120 cm.

-

Screw connection to 7.2, 3/4”. In this thread, the inclination of the long leg is adjusted by turning so that it can be continuously connected to the high-performance cooler 9. The tripod tube 11 is pushed through the cross sleeve 12 to support it and fixed with the wing screw.

-

Double tube with 28 mm outer tube and 22 mm inner tube. Cooling water flows countercurrently between the two pipes and thus absorbs heat. Most of the distillation vapor is liquefied in the core tube, so that the volume is reduced.

-

Cooling water inlet from the cooling water outlet 9.4 of the main cooler via the hose 15. Here, the cooling water coming from the main cooler is introduced.

-

Screw nipple for draining the hot radiator waste water via one of the hoses item 16.

-

Screw nipple for the screw connection of the high-performance cooler (9.), 1/2".

-

-

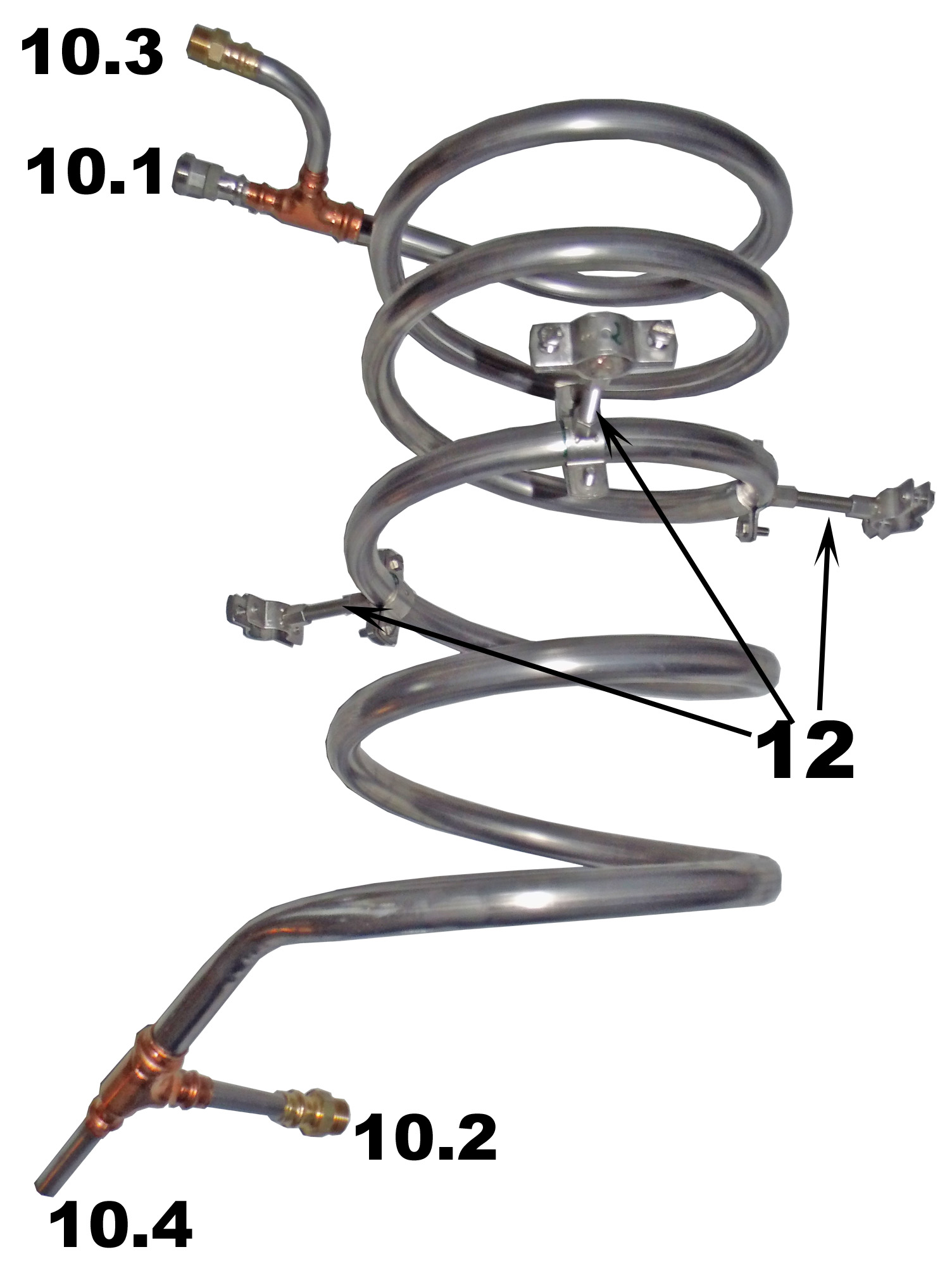

High-performance countercurrent cooler for cooling the pre-condensed hydrolate, stretched over around 6 m length, with

-

Screw connection for connection 8.5, 1/2".

-

Double tube, outside jacket tube 22 mm outside and inside core with 15 mm outside.

-

Cooling water supply via one of the hoses 16, 1/2”.

-

Cooling water outlet for connection to 8.3 via hose 17.

-

Distillate outlet, attaching the distillate hose 18.

.

-

-

3 tripod tubes for stable mounting of the high-performance cooler. The stand tubes are pushed through the cross sleeves 12.1 attached to the cooler and fixed with the wing screws. The cooler is set up in such a way that the spiral windings have a gradient everywhere. The fact that the stand tubes can be tilted and rotated as well as continuously changed in height means that the height of the cooler can be adjusted over a wide range and set up as required. This means that the system can also be set up directly in the harvest field on terrain with uneven ground.

-

Stand tube to support the pre-condenser. It consists of 2 parts due to shipping limitations. The bottom tube has a socket at the top end into which the top tube is inserted. The assembled stand rod is connected to the pre-condenser with the cross socket 12.1 (see above at 8.).

-

Cross sockets for mounting using 11.

-

Connection of the pre-condenser to stand 11.

-

6 cross sleeves for connecting the stand tubes 10 to 6 points on the main cooler 9.

-

-

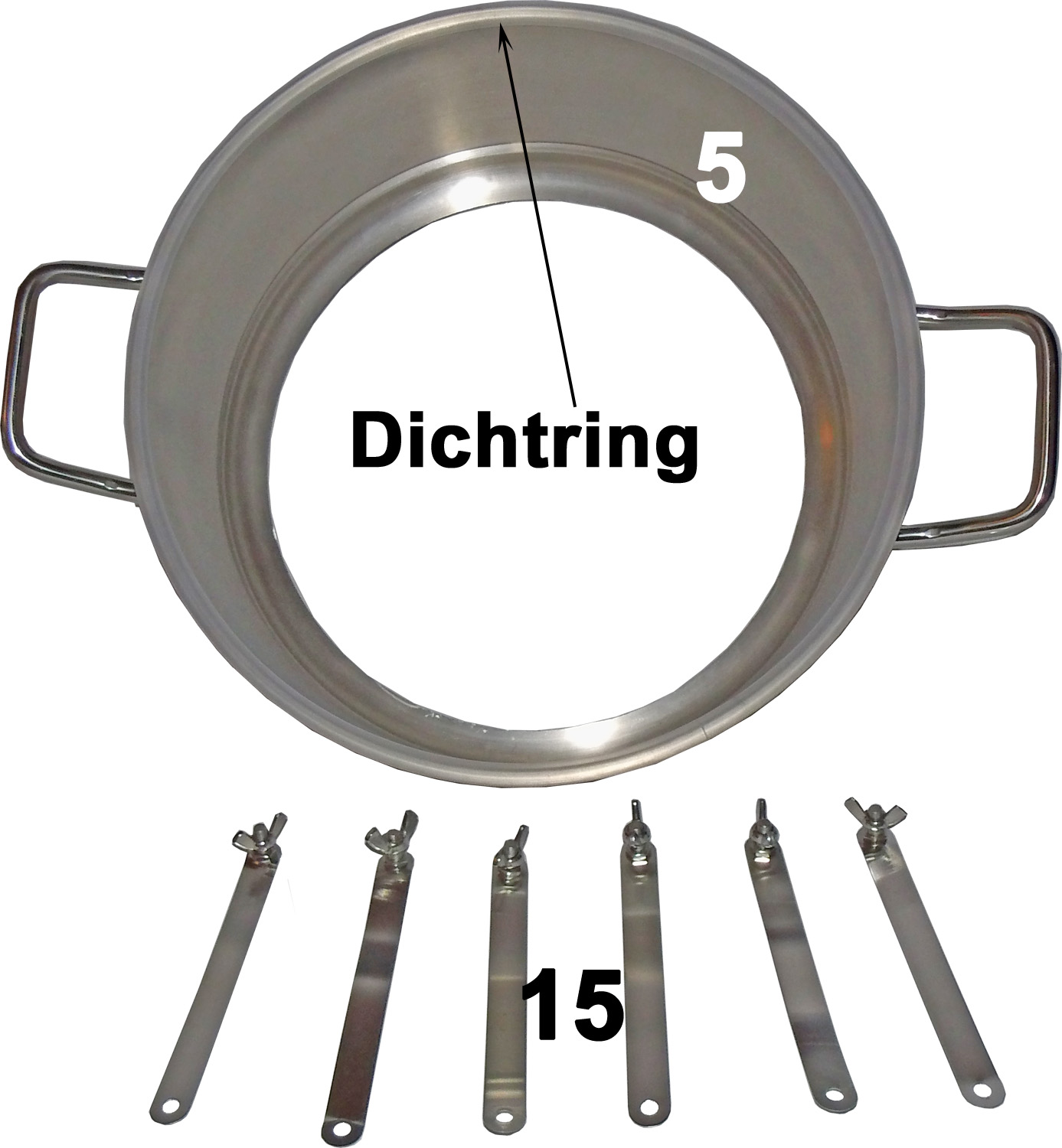

6 tension locks with stainless steel straps to close a system with 2 plant baskets.

-

2 x 6 extensions for operating the system with 3 or 4 plant containers.

-

Hose to connect 8.3, with 9.4. for the cooling water supply of the pre-condenser.

-

2 water hoses for the cooling water supply.

-

Distillate hose for insertion into an oil separator. The distillate hose is simply plugged onto the distillate outlet 10.4.

-

Collapsible sieve with fine perforations when heavily chopped plants are to be distilled. However, note the restriction described under 2. When in use, this sieve is placed unfolded in the lower plant basket (see above).

-

Riser pipe extension for a partial construction.

-

Connector for the plant baskets for emptying bundles before refilling

-

Rolling base with lockable castors for moving out the boiler system when refilling the material to be distilled.

More information

Safe standing when refilling the system

Because the cooling is now fixed at 6 points of the cooling coil, the system's periphery is now more stable when the still is removed for refilling.

This system is optimized in such a way that the bottom of the plant basket does not disturb the steam dynamics and the pressure loss when reducing the cross-section to the cooler is minimized. The plant basket extensions are designed without a bottom so that no drip losses occur when the plant space is multiplied. This avoids an increase in pressure in the boiler and the resulting vapor overheating, which would destroy heat-sensitive essential flavors. This was achieved through a high permeability of the 1st basket floor and a pre-condensation of the oily vapor in the pre-condenser. The steam is fed into the pre-condenser with only a slight cross-section reduction and pre-cooled, so that mostly hot condensed hydrolate is fed into the actual high-performance cooler. This means that the main cooler no longer generates any pressure loss.

Our own investigations with a test system optimized in this way have shown that the differential pressure to the environment in the unfilled system is less than 10 pascals, while before the optimization it was over 1000 pascals. This is a significant improvement and the technical requirements for steam distillation are now optimal.

When loading with plants, you should make sure that they are only poured loosely. Under no circumstances should the plants be compacted, as this can lead to the destruction of the steam dynamics. The ideal filling height of the plant baskets should be determined specifically by experiment. With sufficient steam throughput with fresh plants, it has been shown that 4 to 5 basket units are ideal.

To seal between the individual pots, the supplied profile seals are pulled onto the pot edges in such a way that the short lip is positioned on the outside of the pot edge. The plant baskets are being put on. In order for the steam dynamics to develop sufficiently with direct heating, the water boiler should only be filled with a maximum of 15 liters of water at the beginning. This water is enough for at least 3 distillations of a maximum of 1/2 hour.

The Premium-Plus 2022 model is already fitted with a 1" inlet tap and has an internal diffuser steam inlet device to direct externally generated steam into the boiler with less efficiency loss.

Insulation of the plant container or at least the helmet is also recommended, because oil is lost through condensation here when it cools down. This is largely avoided by insulation. In the case of external steam supply, the boiler should also be insulated. In the simplest case, insulation can be done by wrapping in thermal blankets.

DISTILLING MASTER JUMBO E7448 Premium

Optimized distilling plant for steam distillation for the production of essential oil

Essential oils by steam distillation. The distillation system DESTILLIERMEISTER E7448-Premium is optimized for the extraction of essential oils. It has a maximum drug volume of 48 liters, which can be extended by another 12 liters. Essential oil obtained by steam-entraining distillation has a particularly high quality, because the temperature in the drug container with this method remains below the evaporation temperatures of the water and oils and thus the essential flavors are conserved. Especially the stainless steel distilling devices of the premium models of the DESTILLIERMEISTER E series work with a pressure reducing precondensor, so that with these stills a particularly high product quality is achieved. After condensation of the oil-bearing hydrolates in the precondensor, the downstream high-performance cooler cools the essential oils to the desired temperature.

The DESTILLIERMEISTER E7448 Premium:

-

Solid thick-walled water / steam boiler made of 18/10 stainless steel and three-layer thermo bottom: 25 liters,

-

steam-dynamically optimized plant basket: 12 liters,

-

3 plant box extensions: 12 liters each.

-

Spherical helmet to reduce dripping loss.

-

Insulated standpipe to prevent premature condensation.

-

Precondensor to reduce pressure and temperature to preserve the essential aromas.

-

Counter-current, high performance cooler.

-

With a variable tripod mounted cooling system, so that the boiler can be recharged independently of it.

Construction

-

Boiler for steam production, 26 liters. Maximum water capacity 15 liters.

-

Lower plant basket with large opening ratio, 12 liters. For highly comminuted drugs, the foldable sieve 19 can be inserted. But this should - if possible - be avoided so as not to disturb the steam dynamics. In general, even finer cuts fill in the basket, because the herbs interlock with each other. The parts of the plant that fall through at the beginning can be caught and topped up again.

-

Fixed stainless steel analog thermometer 0 -120 ° C, accuracy class 1 - easy to read.

-

-

Plant box extension without bottom, 12 liters. Up to 4 such extension units can be used with fresh plant material and 3 extension units with dried plant material. This extension can be constructed with the tension locks 13. to the 2-stage model E5024-Premium.

-

Second plant box extension without bottom, 12 liters.

-

Second plant box extension without bottom, 12 liters.

-

Alembic. The sealed screw nipples are prepared for various possible optional applications (pressure measurement, additional temperature measurement, etc.)

-

Screw connection for the riser (7.), 1 ".

-

-

Insulated riser with bend deflection.

-

Screw nipple for the screw connection to 6.1, 1 ".

-

Screw connection for the precondensor (8.), 3/4 ".

-

-

Pre-condenser for the condensation of the water vapor-oil mixture.

-

Screw nipple for screwing to 7.2, 3/4 ". In this thread, the inclination of the long leg is adjusted by turning so that it can be continuously connected to the high performance cooler 9. By turning. By the cross sleeve 12, the stand tube 11 is pushed to the support and fixed with the eye bolt.

-

Screw connection for the high performance cooler (9.), 1/2 ".

-

Screw nipple for the supply of cooling water from 9.3 via the hose 17., 3/4 ".

-

Screw nipple for the discharge of the hot waste water via one of the hoses Pos. 17.

-

-

Connector between precondensor and high performance radiator.

-

Counterflopw high-performance cooler for cooling the condensed hydrolate to the desired temperature.

-

Screw nipple for the screw connection to 9.2, 1/2 ".

-

Cooling water supply via one of the hoses 17, 1/2 ".

-

Cooling water outlet for connection with 8.3 via the hose 16.

-

Distillate outlet, attaching the distillate tube 18.

-

-

5 tripod tubes to stabilize the periphery to allow a re-loading of the baskets without disassembly.

-

3 tripod tubes for setting up the high performance cooler. The tripod tubes are pushed through the cross sleeves attached to the radiator with the eye bolts and fixed with the eye bolts. The cooler is positioned so that the spiral turns almost everywhere have slopes. The fact that the tripod tubes can be both tilted and rotated and can be changed continuously in height, the radiator can be adjusted in a wide range in height and set up as desired. Thus, the plant can also be placed directly in the harvest field on terrain with uneven ground.

-

Shorter plug-in tripod tube. This is connected with a cross sleeve with the lower part of the precondensor.

-

Lower tube with socket for insertion of 11.2.2.

-

Upper tube.

-

-

Longer pluggable tripod tube. This is fastened directly in front of the screw connection for the precondensor.

-

Lower tube with socket for insertion of 11.3.2.

-

Upper tube.

-

-

-

4 cross sleeves for rebuilding by 11.

-

4 cross sleeves for rebuilding by 11.

-

Clamping system for firmly connecting the plant baskets, so that they can be taken out compact, emptied and refilled.

-

2 x 6 extensions for the operation of the plant with 3 or 4 plant containers.

-

Reinforced hose for connecting 8.3, with 10.3. to the cooling water supply of the precondensor.

-

2 water hoses for the cooling water supply.

-

Distillate hose for insertion into an oil separator. The distillate hose is simply put on the distillate spout 10.4.

-

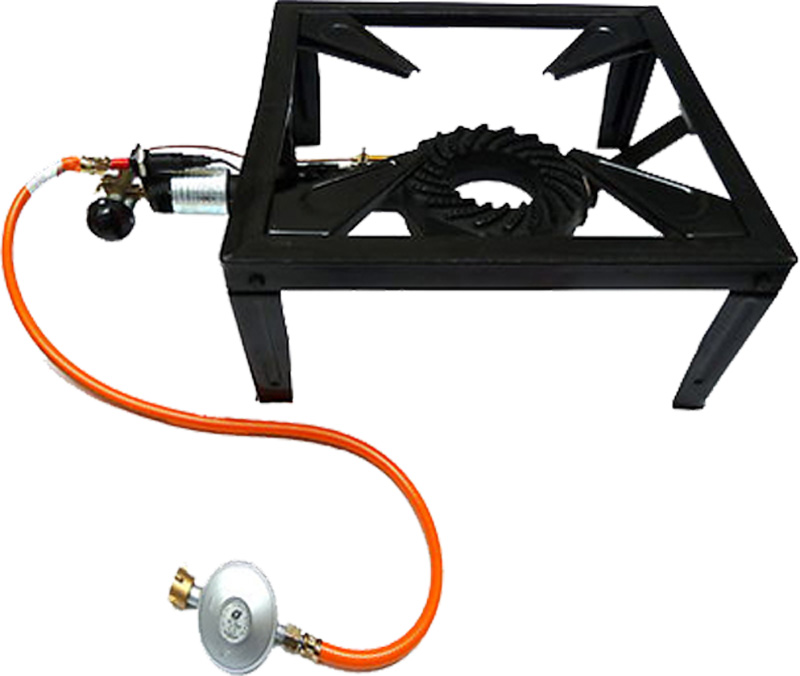

Gas cooker 9.5 kW, IGNITION PROTECTION, PIEZO IGNITION, HOSE, REGULATOR.

The gas cooker is in original packaging and still needs to be installed. The assembly can be ordered as an option. The option price also includes the separate shipping required.

Included in the delivery are:

- Stool 4-legged 10.5 kW,

- Pressure regulator 50mbar,

- Propane hose, 1 meter,

- Ignition fuse (automatic gas stop if no flame is burning),

- piezo ignition.

- Operating pressure: 50 millibar,

- Power 10.5 kW,

- Consumption: maximum about 600 grams / hour,

- Gas type: propane gas,

- Weight: 6.1 kg,

- Outlet for hose connection: 1/4 inch

20. Foldable sieve with fine perforation, if heavily shredded plants are to be distilled. Note, however, the restriction described under 2. This sieve, when unfolded, is placed in the lower plant basket.

More information

This system is optimized so that the bottom of the plant basket does not interfere with the dynamics of the steam and the pressure loss during cross-section reduction to the cooler is minimized. The plant basket extension is carried out without soil, so that doubling the plant space no back drop losses occur. As a result, a pressure increase in the boiler and a resulting steam overheating are avoided, which would result in the destruction of heat-sensitive ethereal aromas. This was achieved by a high permeability of the basket bottom and a precondensation of the oily vapor. The steam is passed into the precondensor with only a small reduction in cross-section and pre-cooled, so that hot condensed hydrolate is introduced into the actual high-performance cooler. Thus, the main radiator produces no more pressure loss.

Our own investigations with such an optimized test facility have shown that the differential pressure to the environment in the unfilled plant is less than 10 Pascal, whereas before the optimization it was more than 1000 Pascal. This is a considerable improvement and the technical requirements for the steam distillation are now optimal.

When feeding with plants you should make sure that they are poured only loosely. Under no circumstances should the plants be compacted, as this can lead to the destruction of the steam dynamics. The ideal filling height of the plant baskets should be determined specifically by experiment. In fresh plants it has been shown that 4 to 5 basket units are ideal. For dried drugs, it should be a maximum of only 3-4.

For sealing between the individual pots, the supplied profile seals are mounted on the pot edges so that the short lip is positioned outside of the pot edge. The plant baskets are placed straight on and evenly pressed. In order for the steam dynamics to develop sufficiently, the kettle should at the beginning only be filled with a maximum of 15 liters of water. This water is sufficient for at least 3 distillations of a maximum of 1/2 hour.

Optionally, a ball valve for refilling water can be installed in the pot. In addition, an external steam supply via a steam generator is possible. For this, the pot must be prepared, which is also possible as an option. Ideal for the DISTILLIERMEISTER E7448-Premium is a steam generator that delivers between 20 kg and 25 kg of saturated steam per hour.

In addition, insulation of the plant container or at least the helmet is recommended because it is lost by cooling oil by condensation. This is largely avoided by insulation. With external steam supply, the boiler should also be insulated. In the simplest case, the insulation can be done by wrapping in thermal blankets.